At Ripley Tools, we know that as cables are constantly evolving, cable prep tools need to evolve rapidly too in order to enable linemen to do their jobs quickly, efficiently and safely.

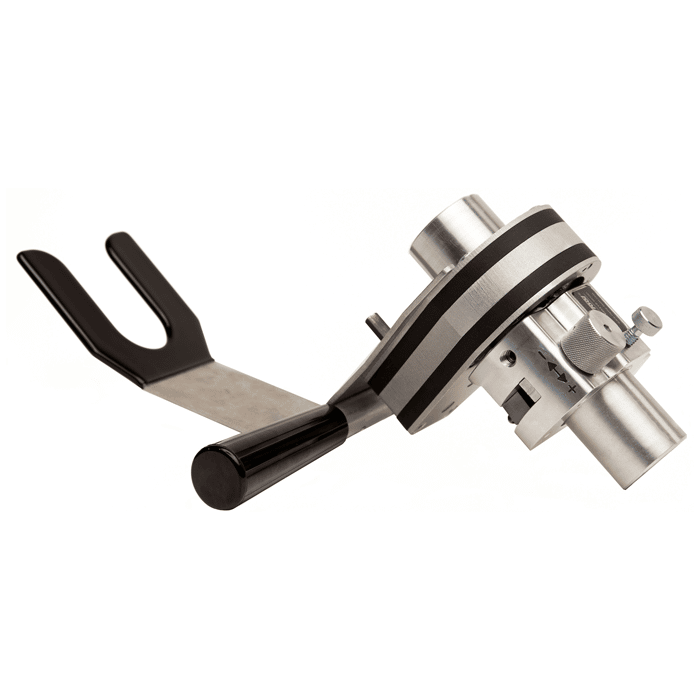

So when we heard of lineman Andy Sedlacek’s idea for a new tool that he believed would make his work easier, the engineers at Ripley Labs couldn’t wait to work with him. That prototype has since been developed into a tool that might already sit within your toolkit – our popular US16 Drill Operated Jacket Removal Tool.

We’ll let him tell you how it got to where it is today – here’s what Andy had to say when we asked him all about the US16.

Q: How did you come up with the idea for the US16?

A: I first came up with the idea for a drill-powered jacket removal tool in 2016 – at that point I’d been a lineman for around 20 years. Jacket removal on power distribution cables is really hard work. It’s very physically demanding to keep repeating the same motions, particularly where I work, in Kansas, where cold weather can really make the outer jackets rigid and difficult to remove. This meant that we were often using a combination of strippers, pliers and knives to perform the task. By contrast, there were other tools in our toolkit that had become automated, so you just had to pull a trigger to use them. I thought that there must be a way that automation could be applied to jacket removal.

Q: How did you turn your idea into a reality?

A: I approached some friends with my idea and within nine months they had produced a fairly crude, but usable, initial concept. I put it in my truck and used it myself for the next six months on primary jacketed cable on the power distribution network I was working on. It was fairly rough and ready at this stage, but I knew that it worked in principle and decided to take development to the next level.

I approached The Technology Development Institute at Kansas State University. They work with inventors and they were really interested, particularly because I already had a working prototype as a starting point. So we started working together to improve my prototype. We initially set out to create just one unit, and we focused on:

• Making it easily adjustable – linemen don’t want to have to manipulate, make changes or add parts to our tools when we’re out in the field, so the tool needed to work quickly and easily on the job.

• Making it easily operable with one hand – because the lineman needs one hand on the cable and one operating the tool. We often work alone, so this is essential.

• Improve the feed-through design – because the tool needed to be open-ended with no stops, so having the right feed-through mechanism for the peeled jacket was vital. Over a longer cable length, quite a lot of thick jacket has to go somewhere as it’s removed, so the tool design needed to address that issue.

• It needed to work for different cable sizes

Together, we spent time trying different iterations to get the tool right. We wanted to make it applicable for different cable sizes, create different sized bushings, make sure the user could mount the drill in the safest and most robust way, and trial different types of blade.

There were some challenges – creating an exit window of the right size for the peeled jacket to feed through took time, for example, as it kept binding around the tool. We spent around a year refining the tool, tweaking elements of the design to iron out any user issues and coming up with something that worked well as a first prototype to demonstrate to utility companies. We also embarked on the patent application process at this point as we knew we’d created something really different.

Q: How did you determine whether there was an appetite for this new tool?

A: As a lineman, I knew that worker fatigue was a real issue, and the US16 really filled a gap in the market – but I needed to prove it. So once we were happy with the prototype, I demonstrated the tool at a Tool Committee Meeting for the power distribution company I was working for.

Ever-changing technological innovations, safety standards and working practices mean that we need to constantly review the tools we’re using, the new ones on the market and any that need to be retired. So my company held these quarterly Tool Committee Meetings to bring together linemen, buyers, standards committee representatives, health and safety specialists and managers from the power distribution company to do just that.

After I presented the tool, the company confirmed that they would consider buying it if I could develop it into a scalable, market-ready tool. This was a huge milestone moment in taking the tool from an idea to reality, as it was a true test of likely adoption. I went back to Kansas State University and shared with them my vision and the feedback from the Tool Committee. We then entered into a new contract to make it market-ready, which involved creating new CAD models, testing, developing and refining the design until such a point that it was ready to launch.

Q: How did you start working with Ripley Tools?

A: In June 2020, the Director of Engineering at Ripley Tools, Brian Bourgoin, spotted a press release that the University had issued on the new prototype. Brian told us that he could really see the opportunity for the tool as part of the established and well-respected UtilityTool® range. We agreed, and so we made a deal for Ripley® to take it to market as the US16 from UtilityTool®.

Brian and team took the US16 into Ripley Labs to make some final adjustments, which were focused on further strengthening the tool and improving the blade and adjustment design. They’ve also worked to expand the application range of the tool, so it can be used for a far wider range of cables than the four medium voltage underground jackets it was originally designed to strip.

The partnership with Ripley works really well – they have really brought my vision to life and made it useful to a much larger group of people across a much wider range of applications. We’re also really close to securing the patent on the US16 now.

Q: Since the US16 has gone to market, what kind of feedback has it received?

A: We’ve had great feedback from linemen in the field and it’s great to see the US16 gathering momentum on the sales front. People like it – they like the simplicity and ease of use. I think they can tell it’s been designed by someone who does the job.

When I first started doing this job over 20 years ago, everything was manual. Today, technological advancement means that in many ways it’s quite a different job. Now nobody drills a hole by hand, and so much of our toolkit is automated – our wire cutters, crimping tools and cutting tools are all automated, and the US16 fits perfectly into this toolkit.

It’s much safer and less demanding on the body, so people can do the job for longer and with lower risk of injury. Not only are there important physical and safety benefits to these technological advancements, it means that we can all work more efficiently too. It’s much quicker and easier now to strip, maintain, join and connect cables, so we can get more done in the same amount of time, and with smaller crews of maybe three people, rather than four or five.

To find out more about our innovative US16 Drill Operated Jacket Removal Tool, and order one for your toolkit today, head to our US16 page.

Products mentioned in this article